- In the field of power electronics, ever greater currents are being realised on smaller circuit boards.

- The size and space of the circuit board in a housing are becoming increasingly tight.

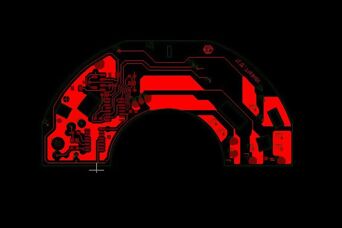

- In the field of sensor and communication technology, the signals are becoming faster and faster and/or a radio antenna is implemented directly on the PCB. The layout must be created according to the teachings and knowledge of so-called «high speed design».

- The variety of layouts in the specific fields has grown considerably, as has the variety of different possible PCB-Technologies. Whether it is the standard FR4 or more specialised FR4, RigidFlex, Flex or even printed plastic parts with copper and assembled components, the world of the PCB-Designer is becoming more and more interesting and diverse.

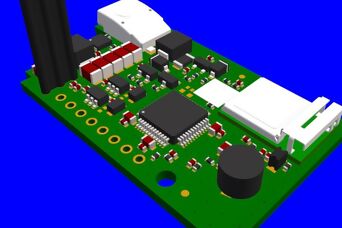

- Nowadays, it is also possible to display the layout in 3D in the layout programme. The components, tracks, etc., can also be moved directly in the 3D view and even integrated into the housing (step model). This means that any collisions between components or even with the enclosure can be detected at an early stage.

PCB-Design - From electronics development to production, everything revolves around the PCB

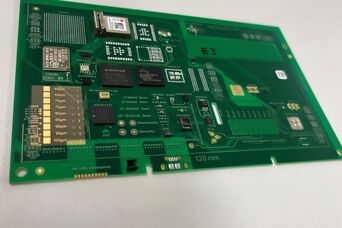

The (mostly) green, copper-coated PCB is a central component in an electronic product and it is impossible to imagine the electronics industry without it. Andreas Höhn, Head of PCB-Design & Electronics Development Laboratory, describes the interface role of a PCB-Designer and highlights the central contribution that a PCB makes to a successful end product.

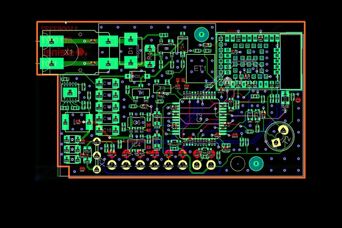

The PCB is the heart of the electronics hardware world. In order for it to be manufactured, a functioning PCB-Design is needed, which is laid out with the most modern tools. Housing space conditions, EMC interference, signal integrity, layer structure, routing, production suitability and other topics are the major challenges that must be overcome.

Technical trend areas such as IoT with numerous interfaces and high data throughputs, as well as wireless connectivity, are omnipresent in the electronics industry. With them, the requirements for products have also changed significantly in recent years.

PCBs through the ages

In the past, a PCB-Layout consisted of THT components, tracks and a few vias, which could be created with a simple layout program. Alternatively, the layout was even masked off by hand with black tape and the PCB exposed and etched «in the basement». The layout was only created in 2D.

In this day and age, creating a layout is more complex in many respects; it is no longer just a matter of placing components and drawing conductive paths. Because the requirements for an electronic device have also changed over time and with them the requirements for a PCB-Layout and equally for the PCB-Designer in the implementation.

Expertise and interdisciplinary collaboration

Along with the demands on a PCB-Layout, the role of the PCB-Designer has also changed - it is complex, interesting and diverse. Sophisticated layout programs, multi-layered electronic hardware and trend topics that are developing rapidly require a great deal of specialist knowledge. Continuing education is therefore part of the core mission.

The success factor for successful product development is close cooperation and constructive exchange with various internal and external specialist departments.

Click on the orange dots to get an overview of the interfaces to the individual specialist departments.

Electronics development

Close cooperation with electronics development is the first milestone in creating a layout. Here, topics such as EMC, temperature resistance, currents, placement, technology, etc. should be taken into account right from the start. Likewise, the right choice of components, and if necessary already a procurement solution for the most important components. For sample or prototype production, the PCB-Designer supports the PCB assembly and procurement of components.

Housing design

The size and space conditions of the PCB in an enclosure require close consultation between enclosure design and PCB-Designer, the eternal «chicken-and-egg» discussion between beautiful design of the enclosure and the inner workings of the final product should be avoided here. Usually, the milestone space estimate helps in advance. If the enclosure is already specified, it can sometimes be difficult to create a functioning layout; often millimetre changes in the design or small replacements of buttons solve a problem. Through regular technical exchange, precisely these problems can be solved together at the outset.

Test equipment construction

To ensure that the assembled PCB can also be tested, a test device is needed. At STEINEL, we have our own InCircuitTest department and a Functional Test department. To build a test device, it is imperative that the PCB-Designer and the test device department work together. The placement of the test points, catch holes, etc. on the layout must be coordinated with the test equipment. This coordination step should be done as early as possible.

Purchasing

In the area of PCB-Procurement, the PCB-Designer supports the purchasing department with technical aspects in the choice of PCB and PCB-Manufacturer, because in terms of quality, manufacturers sometimes differ enormously. Finding the right PCB-Manufacturer for a product is not easy and for certain layouts, once more complex specifications of a PCB have become standard. Technical queries from the manufacturer are usually answered directly by the PCB-Designer and feasibilities of PCB-Production related to the complex layout are discussed with the manufacturer.

Technical office

The PCB-Designer works together with the technical office on various topics. This may be in the preparation of a quotation for a customer, whereby, for example, the production benefit is estimated in order to calculate the lead time, the checking of an SAP parts list for the assembly and mounting of the PCB, or the maintenance of existing products.

Project Management

The close cooperation with the project manager makes it possible to keep to the schedule and ensure that it does not get out of joint due to a PCB that is delivered too late. In the same way, the PCB-Designer is involved in the communication with the customer when certain changes in the layout are planned, or when suggestions for solutions are required as to how the design of the product can be implemented more cheaply, more simply or more conveniently for production.

Incoming goods

In order to ensure that received PCBs have been delivered correctly, the PCB-Designer supports the incoming goods department in checking the correctness and quality of the delivered PCBs.

Production

Early cooperation in the development of a PCB-Layout with production is absolutely central, regardless of whether the PCB is later processed in SMD or THT production. The implemented designs must first and foremost be producible. Therefore, it is of high importance to discuss with the production the possibilities of a placement machine, solderability of the component, quality of the PCB, spacing of components and much more. For later series production, the PCB-Designer provides the necessary data for the placement machines, SPI, AOI and manual placement.

Electronics Laboratory

Electronics development usually needs a sample PCB very quickly at the start in order to test the circuit developed. To speed up this process, prototypes are assembled in-house at STEINEL in small quantities and tested in the company's own EMC laboratory. The electronics lab and the PCB-Designer work together on solutions and optimisations for a functional, producible PCB-Design.

Quality Management

If there are production problems on the basis of printed circuit boards or the assembly of electronic components, the PCB-Designer is involved in the joint solution-finding process between the specialist departments. The PCB designer also provides specialist support to the quality department in the analysis of incorrectly delivered PCBs.

Sales

Through the cooperation between sales and PCB-Designer, any special customer requirements can be assessed in advance and thus certain misunderstandings can be prevented for the preparation of a guideline quotation. The PCB designer also provides technical support here for PCB-specific questions.

Customers

In most cases, open questions from the customer are answered by the customer-facing contact persons in sales, project management or the technical office. If the questions are more technical, the electronics development department and the PCB-Designer are available to clarify the open points directly with the customer. In certain projects, the PCB-Designer even works very intensively with the customer.

The many interfaces show: At STEINEL, the PCB-Designer is not «just» a layouter, but also a team player, solution finder, coordinator, reviewer, listener and supporter for the various specialist departments. This is how a successful product is created.

«Our custom OEM products and projects always challenge me and make my profession varied, because it's my job to dutifully implement all the rules and standards and create a working PCB-Design so that it is fit for production and the product is a success - all in an interface role.»