The art of understanding heat.

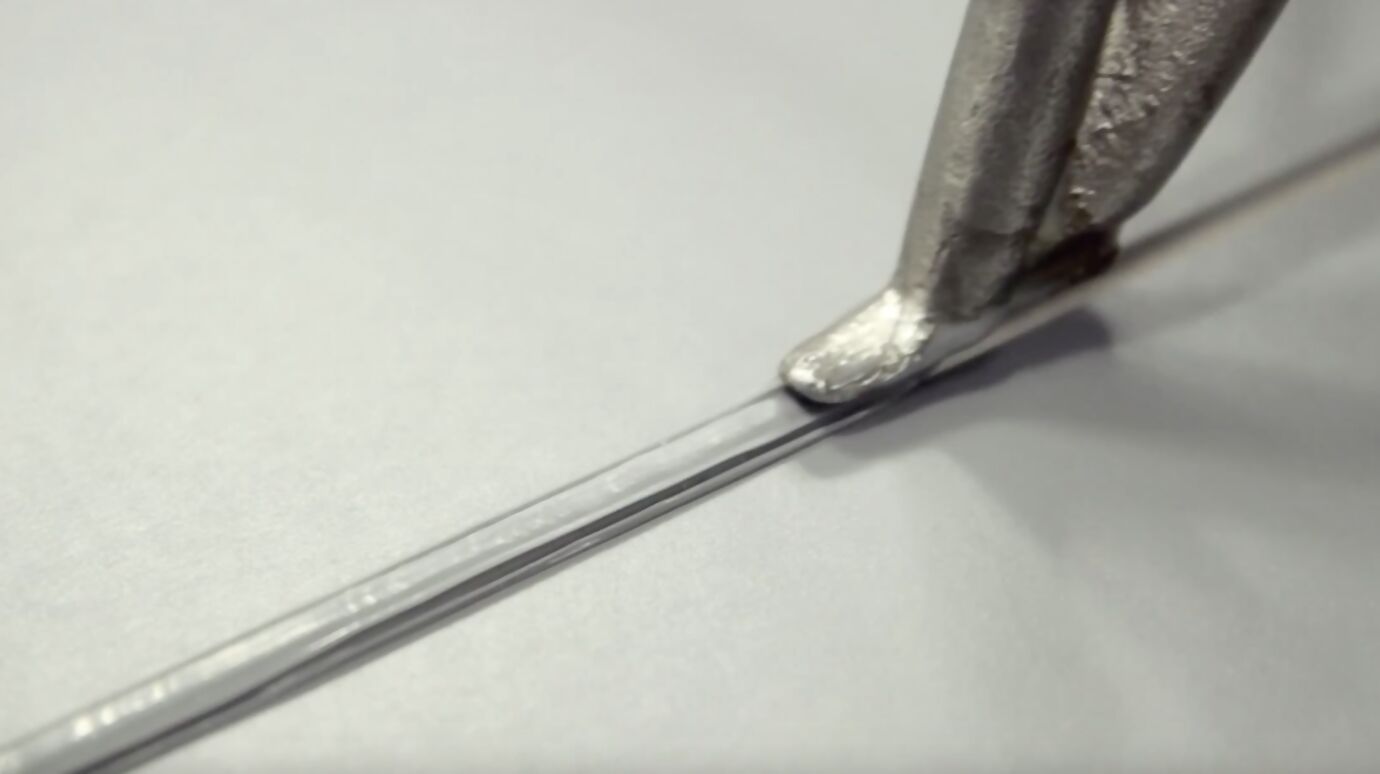

For hot air tools, producing high temperatures is a must; always being in control of them the icing on the cake. And to score top marks on both counts, STEINEL only uses top-quality, long-lasting components that come from its own development forge. And puts them together with meticulous care. This is where our customers benefit from over 30 years of experience in developing and manufacturing hot air tools to give them a product that has been cleverly engineered in every last detail, only delivering heat where it is needed. Across the board.