Our development competences at a glance

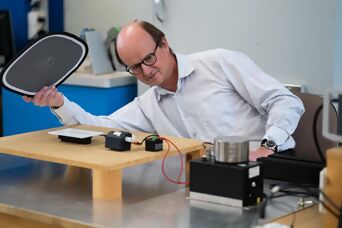

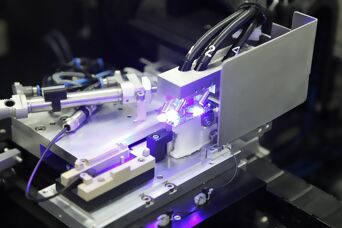

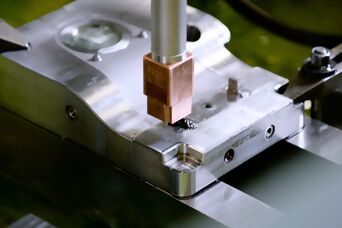

- Electronics

- Mechanics

- Design & Feasibility Study

- Assembly & testing concept

- Prototypes

- Tooling & equipment

- Approval management

- Packaging concept

Development portrait of STEINEL Solutions AG

The requirements for products have changed over the years in many industries - today they have to be intelligent and networkable. The buzzwords building automation, data monitoring, Internet of Things, Bluetooth Mesh, to name but a few, are omnipresent.

And the wheel does not always have to be reinvented. In April 2021, the company launched a successful product portfolio with sensors for light installation running under the «SENSOTEC» brand. In addition, a large number of existing solutions, product or technology platforms from STEINEL serve as the basis for OEM variants with the minimum requirement of optical and/or functional modification.

Recommendation

«Developing products for clients from different markets with changing challenges makes our work incredibly exciting and varied. Our range of expertise and services brings huge benefits and advantage to clients.»